|

Simplified surgery and long-term stability |

|

Simplified surgery and long-term stability

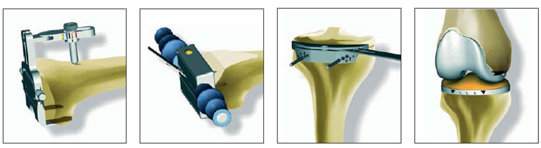

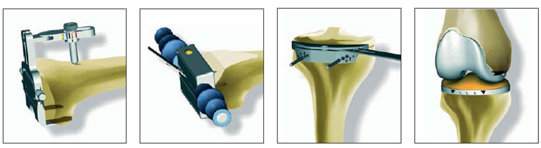

The following criteria define the quality of the implantation: the precise alignment of the prosthesis along the mechanical load axis, the reconstitution of a well-balanced tension in the soft tissue, the anchoring of the implant in sufficiently sturdy bone, and the proper selection of the sizes for the various components of the prosthesis. All of these requirements were borne in mind when the ÆQUOS instruments were designed. It is important to note that the anatomically natural design of the implant significantly facilitates the surgical procedure.

|

|

The relative alignment of the components is made easy by the fact that there is only one exact way all the various pieces fit together under load. The tibial implant snaps into place by flexing and extending the knee under a slight load.

The complex movement of the ÆQUOS G1 joint closely resembles the movement of the natural knee. As a result, the ligaments and muscles are not unduly stretched or loosened. Releasing one of the ligaments is rarely, if ever, necessary.

The joint moves by friction-less rolling, a stark departure from previous knee implant designs.

Because of the fact that the rolling motion dominates during peak loads, the tibial plateau and thus the interface with the bone are exclusively loaded by forces that are perpendicular to the surface. This allows the use of conventional methods to anchor the components to the bone. The tibial plateau is fixed by cementation and by a central stud. The primary rotational stability is ensured by two lateral studs.

No auxiliary constructions (studs, mobile bearings etc) are needed. This allows for the procedure to be carried out in little time and in a manner that is easy on the bones.

The physiological slope is part of the tibial joint surface. The tibial joint without slope can be readily resected. The final axial position can be adjusted at some later point in time

|

|

To improve the adhesion of the cement, the underside of the metal plate is sprayed with corundum. The femoral component, whose inner box is also treated, can be anchored with or without cement. The inner box of the femoral component has a planar surface in the region of the facies patellae . Therefore, no additional bone resection is required in this

area and the final lateral alignment can be adjusted at some later point in time.

|

|

Hallmarks of the ÆQUOS instruments:

|

Intra- and extramedullary alignment and more ways to manipulate the tibia and femur

Reproducible bone sections because of precise dissection calipers (all sections are mechanically guided)

A rotational alignment of the caliper used for the resection of the femur is not needed because a rotation by 3 deg is included in the anatomical design of the femoral component

Color and alphanumeric codes simplify the surgical procedure

|

|

|

|